Due to margin pressure, tool costs are an important foundation for the success of products, both in the quotation of costs and in the purchase price analysis of tools. It is important to have detailed and reliable information on tool costs early in product development.

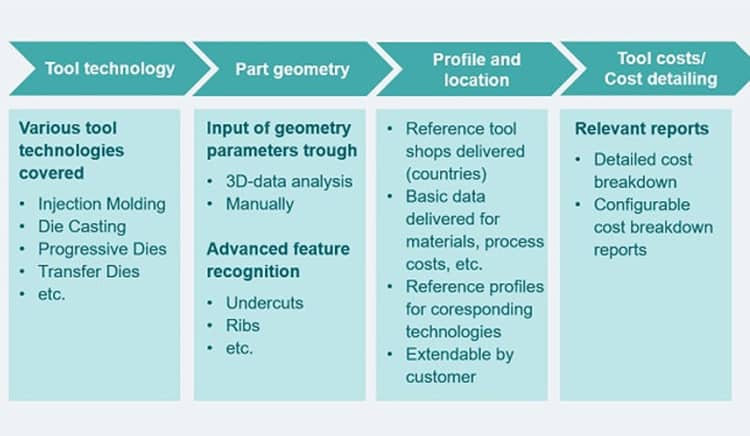

With Teamcenter tool costing, you can create valid tool cost calculations faster, with detailed cost breakdowns. Part geometry can be described manually or using feature recognition software (NX Feature2Cost).

Teamcenter tool costing enables a parametric calculation of various tool technologies such as injection molding, high pressure die casting and progressive die stamping. The integrated knowledge database includes reference data such as labor costs, materials, machines and processes, as well as an integrated process times, ensuring an enterprise-wide consistent calculation standard.

For the tasks within the purchase price analysis, cost engineers can use the Teamcenter solution for tool costing to do shadow calculations as a plausibility check on the calculations of their suppliers. They can use Teamcenter tool costing information such as technology data, part descriptions or 3D-data to create cost calculations using the parametric methodology.

Global procurement markets and increasing cost pressures require professional cost management in the field of mold, tool, and die. Shorter lifecycles paired with higher product variability mean that the share of tool costs in relation to the total costs of a product line is steadily increasing. Therefore the tool costs become a critical focus of cost management in tool purchasing.

Tool buyers need to constantly optimize tool spending and ensure the improved offer performance of suppliers. Due to the increasing complexity of tools and smaller production runs, this balancing act is a challenge even for experienced tool specialists, and succeeds only with the help of a powerful tool purchase prices analysis system that delivers faster, more accurate and comprehensible results based on parametric models.

Your benefits

The design-to-cost capability in Teamcenter product costing helps you to save significantly costs without compromising functionality and quality. You can make smarter decisions for product design that will meet your cost targets.

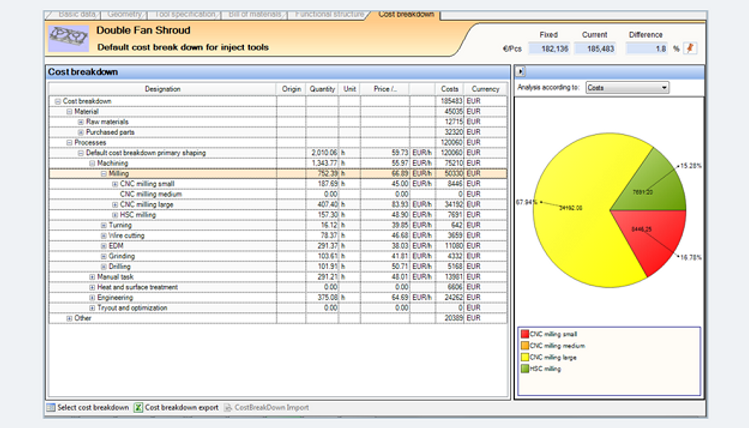

The quoting process for tooling must be reliable and inexpensive, with precise tool calculations and transparent cost breakdowns in a short time frame. The parametric calculation methodology in Teamcenter tool costing enables an optimum balance between accuracy and time-based calculation effort.

Global procurement markets and increasing cost pressures require professional cost management in the field of mold, tool, and die. Shorter lifecycles paired with higher product variability mean that the share of tool costs in relation to the total costs of a product line is steadily increasing.

Tool makers are challenged to quickly create reliable quotations and transparent cost breakdowns for tools. Due to increasing complexity of tools and smaller production runs, this balancing act is a challenge even for experienced tool specialists, and succeeds only with the help of a powerful tool quotation costing system that delivers faster, more accurate and comprehensible results based on parametric models. For tool manufacturers, increasing product variety and shorter product lifecycles means an increased volume of work through a higher number of requests for quotations. The tool quotation costing process must be reliable with precise tool calculations and transparent cost breakdowns in a short time frame.

The parametric calculation methodology in tool quotation costing enables an optimum balance between accuracy and time-based calculation effort. Simulations of technical and economic scenarios help toolmakers to get effective answers to these questions:

Where to produce?

What are the impacts of changes in commercial factors such as labor rates, raw materials or prices for purchased parts?

What are the impacts of changes in technical parameters such as product or design variations,manufacturing technologies and materials?

With tool quotation costing, tool manufacturers can also easily document costing histories and changes, and quickly and flexibly provide the required cost breakdowns in customer templates. In case of recurring changes, a quick and secure creation of cost breakdowns with Teamcenter means a competitive advantage for tool manufacturers.

Your benefits

Using the tool quotation costing capability in Teamcenter tool costing, tool manufacturer can develop highly accurate quotations and cut the time periods for proposal preparations significantly. Sales team can successfully lead negotiations, enforce prices, keep accurate records, and act as a competent partner.

The quality and design of a tool affects not only the tool costs, but also the cost per piece of manufactured parts. The Teamcenter solution offers a unique opportunity to determine the interactions between component and tool costs at different volumes, and makes tool designs reliable and transparent. You can use the combination of Teamcenter tool costing and the Teamcenter product costing for a fully integrated calculation solution. In addition, the tool costs within the integrated solution are considered holistically through the product bill of materials and the product/project program.

Want to make your company more profitable?

Pages